Essential Devices and Strategies for Effective Lead Offense Clean-up

Addressing lead infractions properly necessitates a thorough technique that blends the right tools with calculated approaches. Simultaneously, the use of specialized cleaning devices, such as HEPA vacuum cleaners and lead-specific cleansing agents, is imperative for comprehensive contaminant removal. Effective containment methods, including plastic bed linen and unfavorable air pressure systems, are vital to stop the spread of harmful products.

Personal Safety Devices

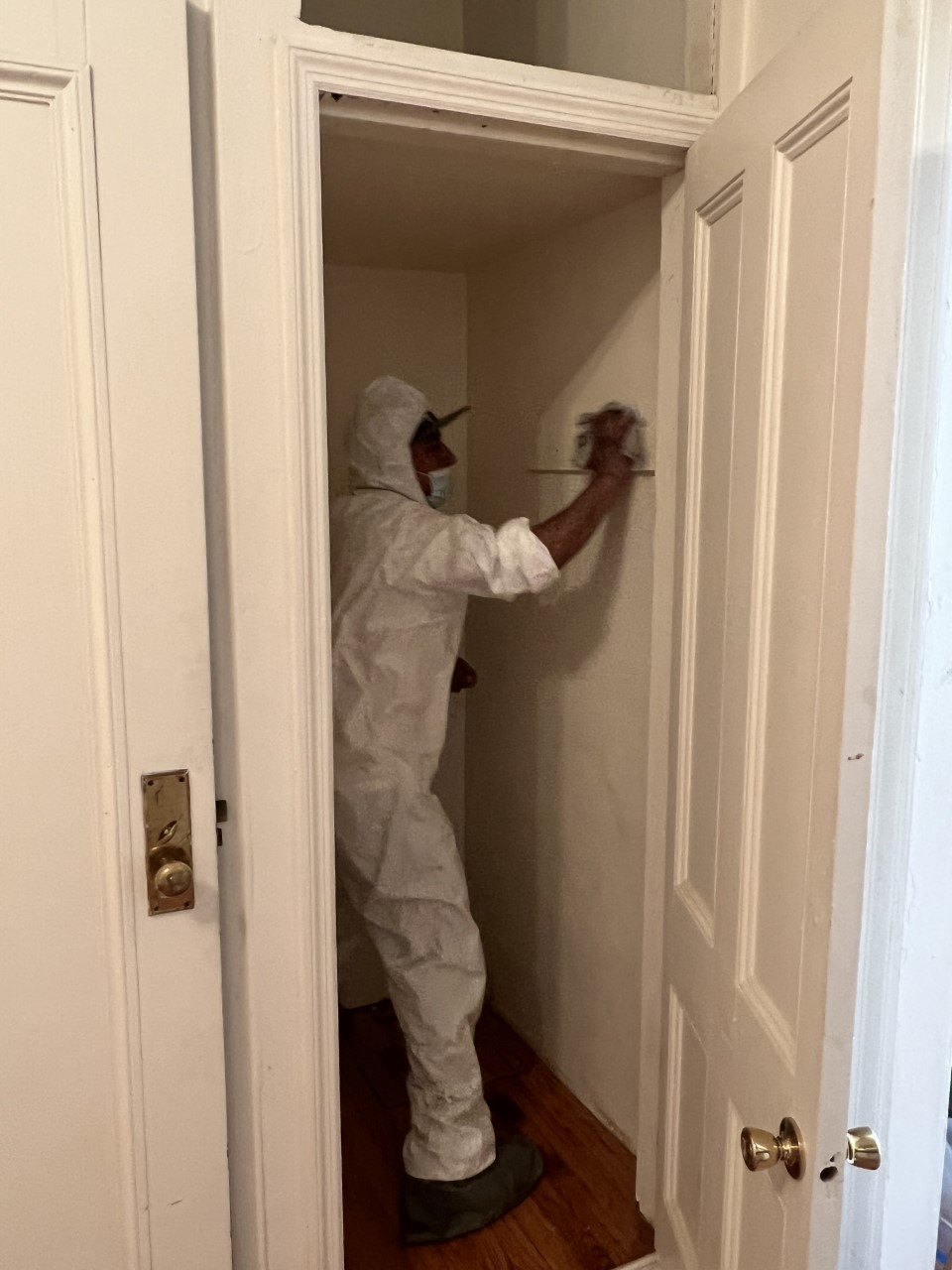

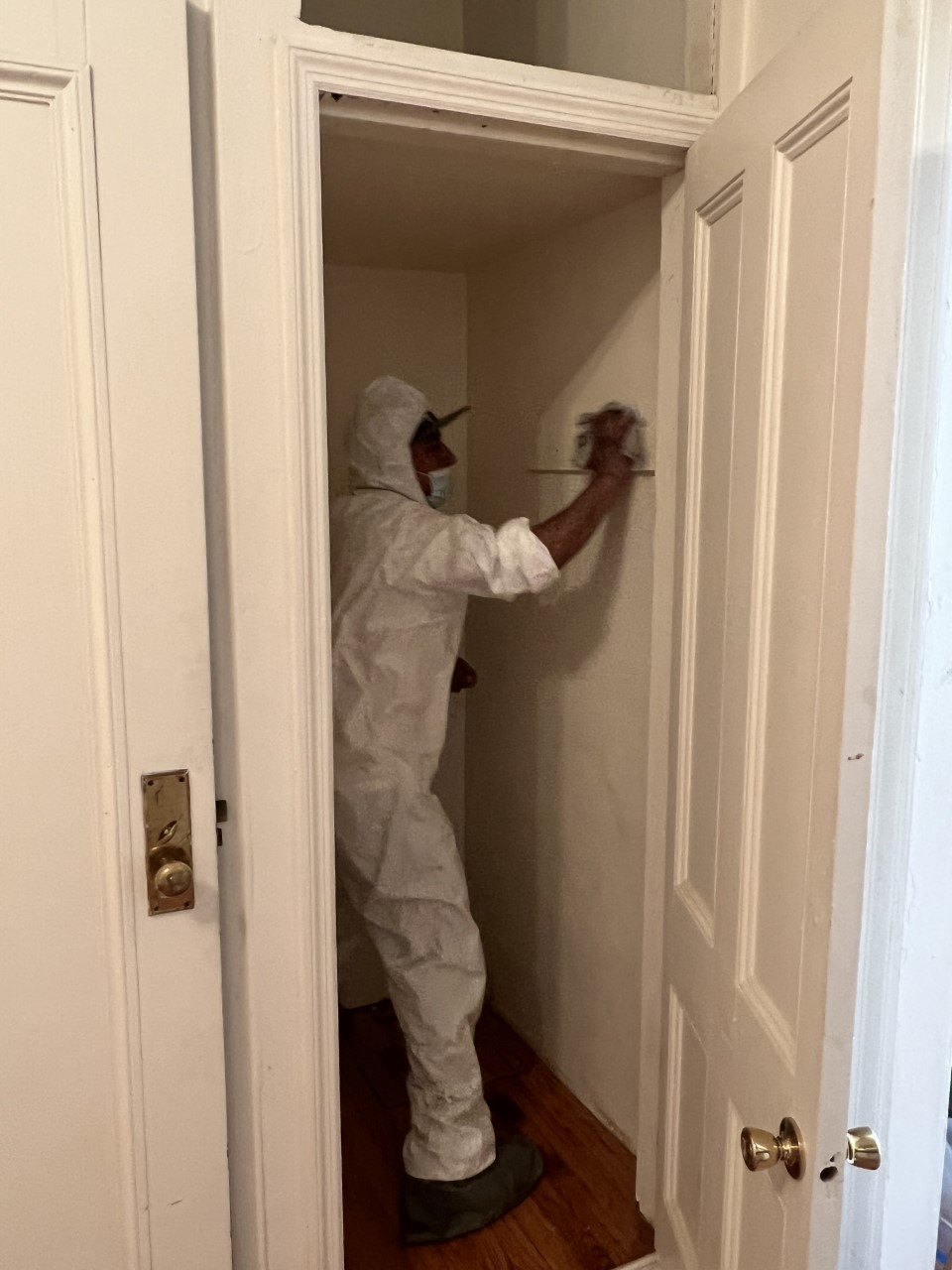

Personal safety tools (PPE) is an important part in the efficient management of lead contamination cleanup. The vital PPE for lead cleaning consists of respirators, protective clothes, gloves, and eye security.

Respirators, specifically those outfitted with HEPA filters, are vital for filtering system air-borne lead fragments, stopping inhalation. Appropriate fit and seal checks are crucial to guarantee their efficiency. Safety clothing, including coveralls and disposable suits, protects against lead dirt from adhering to workers' garments, reducing the threat of secondary contamination. Gloves, normally made of nitrile or latex, protect the skin from direct call with lead, while security goggles or full-face guards safeguard the eyes from dust and debris.

In addition, rigorous training on the correct use and upkeep of PPE is vital. Employees have to be informed on wearing and doffing treatments to prevent contamination. Normal evaluations and replacements of PPE parts are necessary to keep their protective capabilities, making sure a secure and compliant cleaning operation.

Specialized Clean-up Equipment

An additional important tool is the wet/dry vacuum cleaner, which can effectively tidy up both dust and fluid pollutants. These vacuums usually come with HEPA filters to give an extra layer of security. Wet wipes or tack towels are additionally essential for surface area cleansing; they are especially made to catch and hold lead fragments, decreasing the risk of spreading out contamination.

For even more stubborn down payments, specialized lead-removal cleaner are required. These agents are created to damage down lead bits, making them simpler to remove. Scrub brushes with tough bristles can aid in this process, especially on harsh surfaces where lead dust tends to adhere much more strongly.

Furthermore, encapsulants are used to secure lead-contaminated surface areas, protecting against the release of lead dust. These specialized paints and coatings are designed to abide by various substrates, giving a long-lasting service for lead control.

Efficient Control Methods

Efficient control methods are critical in minimizing the spread of lead contamination during clean-up tasks. Implementing durable containment techniques guarantees that lead particles do not move to untouched locations, thus protecting both employees and the environment (DOH & HPD Lead Violation Removal NYC).

To enhance control, encapsulants can be put on surface areas that are not being removed or disrupted. These specialized coatings bind lead dirt, decreasing its availability for resuspension. Furthermore, all employees should wear proper Personal Protective Tools (PPE), including respirators and disposable matches, to prevent contamination spread.

Safe Disposal Practices

Making sure secure disposal techniques is an essential part in the monitoring of lead contamination cleaning. Correct disposal alleviates the danger of lead returning to the setting and threatening public health and wellness. The first step is to determine and segregate lead-contaminated waste from various other products. Protected control making use of durable, leak-proof containers is important to stop splilling during transport.

Transferring lead waste calls for adherence to stringent guidelines. Making read what he said use of accredited contaminated materials carriers guarantees that the products are handled responsibly. Documents, consisting of manifests outlining the type and quantity of waste, should accompany shipments to track the waste from the site hop over to these guys of beginning to its last disposal destination.

Designated harmful waste disposal centers are furnished to deal with lead-contaminated products safely. These centers frequently employ advanced approaches such as stablizing, solidification, or chemical treatment to counteract the lead prior to disposal. Landfilling in specialized, lined areas that protect against leachate from polluting groundwater is an usual method for final disposal.

Normal training for workers entailed in lead garbage disposal is essential to maintain safety requirements and avoid unexpected direct exposure. By adhering to these techniques, companies can substantially decrease the ecological and health influences related to lead contamination.

Regulatory Conformity Tips

Sticking to governing conformity is critical in the effective execution of lead contamination cleaning. Comprehending and following government, state, and neighborhood laws makes certain not only the safety and wellness of individuals however additionally the legal and economic health of the clean-up company. The Epa (EPA) sets stringent requirements, such as the Lead Restoration, Repair, and Paint (RRP) Regulation, which mandates correct accreditation and training for specialists managing lead-based tasks.

Conformity starts with a comprehensive analysis of relevant laws and policies. Organizations must remain updated on any legislative changes, which can be assisted in through routine training sessions and subscribing to sector updates. Documentation is an additional critical compliance element; keeping thorough records of all tasks, including assessment reports, employee training logs, and disposal manifests, is important.

Additionally, involving with accredited lead inspectors or risk assessors ensures that lead dangers are correctly determined and reduced. Employers must apply the usage of Individual Safety Tools (PPE) and ensure that security protocols are strictly followed. Clear interaction with stakeholders, consisting of staff members, customers, and governing bodies, will certainly promote a society of compliance and accountability, ultimately contributing to a safer and more effective lead cleaning process.

Final Thought

Efficient lead violation cleaning requires the integration of specialized tools and tactical techniques to make sure security and efficacy. Making use of HEPA vacuums, specialized cleaning agents, and visit homepage effective containment methods such as plastic bed linen and unfavorable atmospheric pressure systems is imperative. Personal safety devices (PPE) safeguards employees from direct exposure, while safe disposal methods and strict adherence to regulatory conformity are essential for responsibly handling contaminated materials. Collectively, these steps dramatically reduce wellness threats and add to a cleaner environment.